Jan. 26, 2026

In modern industrial systems, turbine oil serves as the "blood" of key equipment such as steam turbines and gas turbines, and its cleanliness and moisture content directly affect the safe operation and service life of the equipment. Traditional oil filtration equipment often fails to meet the increasingly stringent requirements for oil purification, while turbine oil vacuum oil purifier, with their innovative triple purification technology, are redefining the standards for industrial oil maintenance.

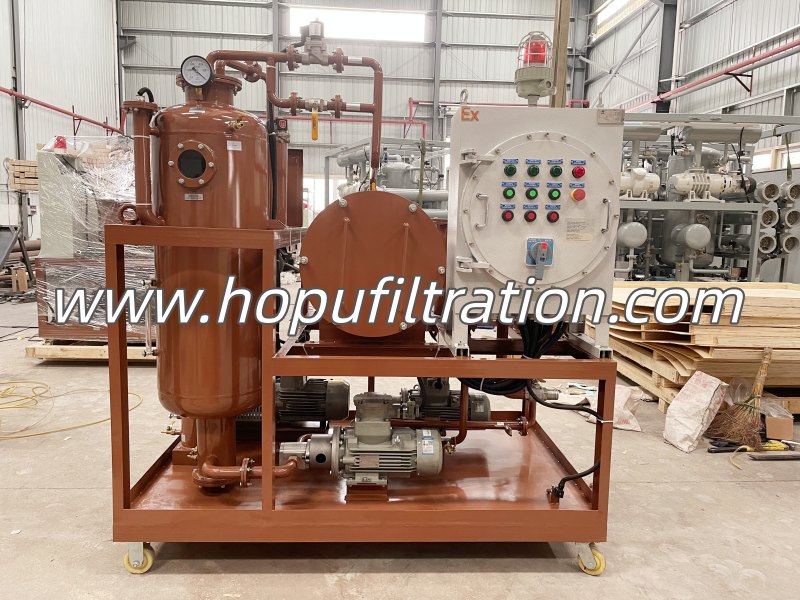

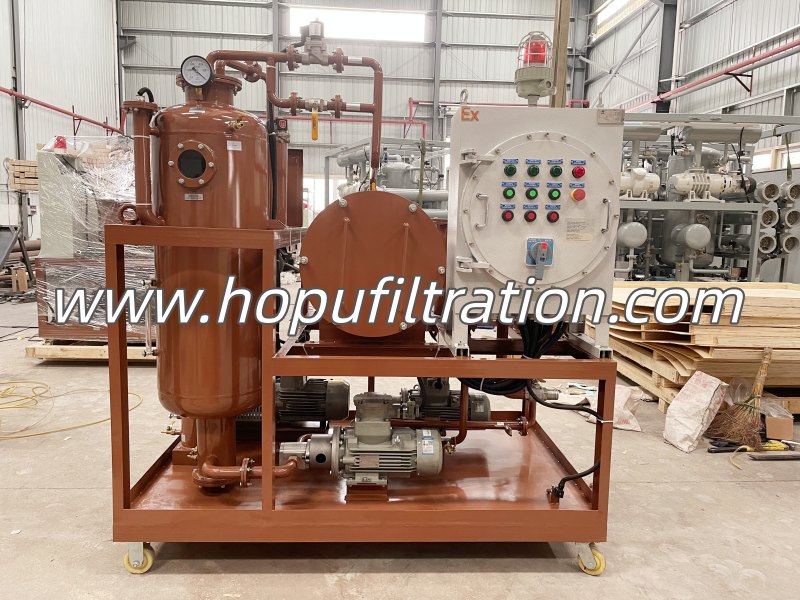

HOPU Teams designed Explosion Proof Vacuum Turbine Oil Purifier to meet the above requirements.

Core technological advantages Coalescence separation filter element: a breakthrough in precision filtration innovationHOPU turbine oil vacuum purifier adopts advanced coalescence separation filter technology, achieving a qualitative leap in impurity removal efficiency. This specially designed filter element, through a multi-layer composite structure, can effectively capture solid particles with diameters as small as 1 micron, including metal wear particles, oxidation products, and foreign pollutants. The agglomeration effect causes tiny water droplets to gradually aggregate into larger droplets on the surface of the filter element, creating ideal conditions for the subsequent vacuum dehydration process. Actual application data shows that the impurity removal efficiency of this system can reach over 99.5%, far higher than the 85-90% level of traditional filtration equipment.

Vacuum dehydration system: key technology for deep purificationThe efficient vacuum dehydration system equipped with the equipment is the core of removing water from the oil. This system significantly reduces the boiling point of oil by creating a vacuum environment of -0.08 to -0.095MPa, and can achieve rapid evaporation of water under mild conditions of 40-60 ℃. This low-temperature treatment method not only avoids the damage of high temperature to oil performance, but also effectively removes three different forms of water: dissolved water, emulsified water, and free water. The water content of the processed turbine oil can be reduced to below 50ppm, reaching or even exceeding the new oil standard, ensuring reliable operation of the equipment under extreme working conditions.

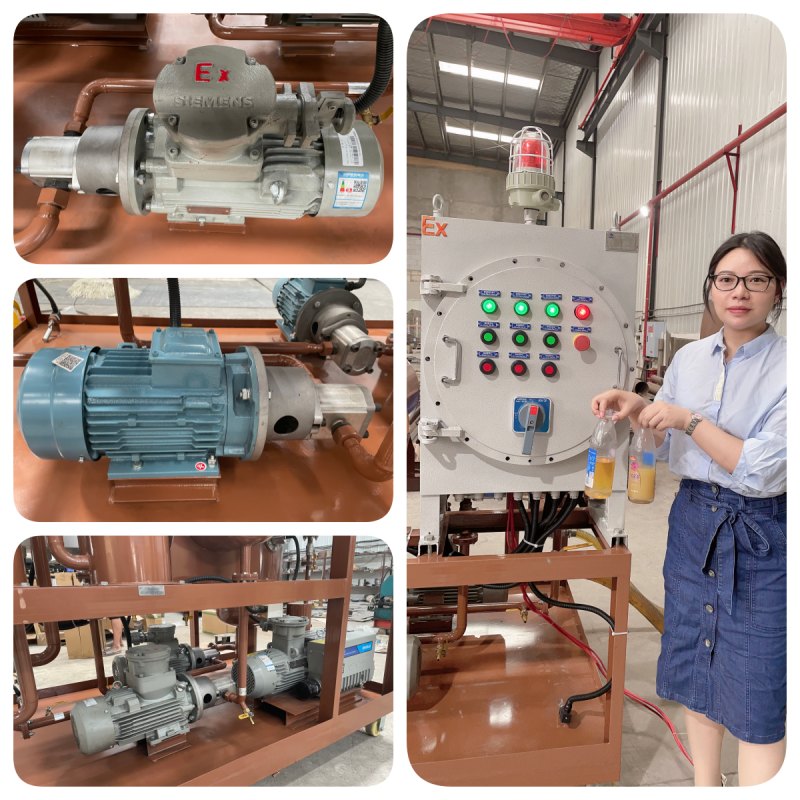

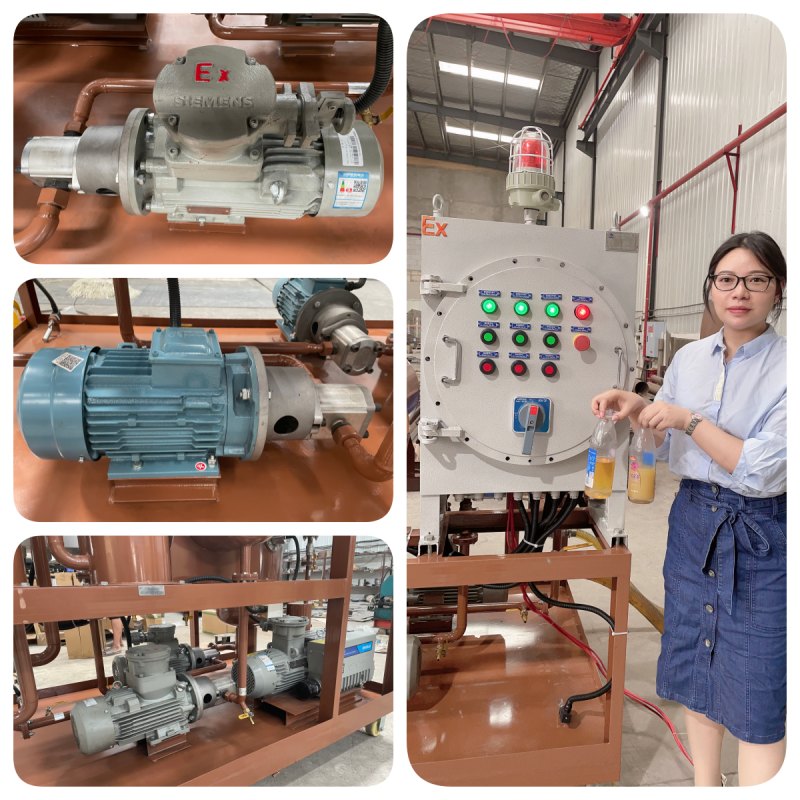

Explosion proof safety system: a reliable guarantee for industrial environmentsConsidering the potential risks of flammability and explosion in industrial sites, the turbine oil vacuum filter is specially equipped with a comprehensive explosion-proof safety system. The equipment adopts explosion-proof motors, explosion-proof electrical control boxes, and anti-static designs, and is manufactured strictly in accordance with Ex d IIB T4 explosion-proof standards. The system is equipped with multiple safety interlock devices, including temperature monitoring, pressure protection, and liquid level alarm, to ensure automatic shutdown protection in any abnormal situation. This intrinsic safety design enables the equipment to operate safely in high-risk environments such as petrochemicals and coal mines, providing a solid guarantee for the safety production of enterprises.Overall performance

The three core technologies of the turbine oil purifier work together to form a powerful comprehensive purification capability. Actual operating data shows that a single device can process 1000 liters of contaminated turbine oil (with a water content of 1000ppm and impurity content NAS level 12) within 8 hours to a high-quality standard with a water content below 50ppm and cleanliness reaching NAS level 5. This efficient purification capability not only extends the service life of turbine oil by 3-5 times, but also significantly reduces equipment maintenance costs and downtime.