Vacuum Insulation Oil Dehydration and Degassing System,Two Stage Vacuum Transformer Oil Purifier is widely used for industries of power plant, power station, electricity company, transformer factory, metallurgy, petrochemical, mechanical engineering, transportation, railway and transformers manufacturing etc. Especially, it applies to maintenance of transformers above 110KV and deep purification of high grade new transformer oil, imported transformer oil, mutual inductor oil and ultra high voltage transformer oil. It can be also used for oil vacuum filling and vacuum drying as well as transformer vacuum evacuation operation. Moreover, the machine can be working online without stop of transformers.

Application

It can quickly and effectively remove moisture, gas (Hydrogen, acetylene, methane, etc.) and impurities from the insulation oil, to improve the oil dielectric performance. The filtered oil can effectively ensure the power equipment run safely and normally.

ZYD Double-stage vacuum oil purifier,Vacuum Insulation Oil Dehydration and Degassing System is widely used in power supply, power generation, power transmission and transformation, power equipment manufacturing, power engineering, electrical equipment maintenance, power testing, electrical research and other industries. It is especially suitable for the filtration of high-grade transformer oil and ultra-high transformer oil, and can be applied to online oil filtering operations at the power substation (like 110KV / 220KV / 500KV).

Meanwhile, It has the functions of vacuum drying, vacuum oil injection, and hot oil circulation. It can also be used as a separate vacuum pumping unit to evacuate transformers and power equipment.

Feature

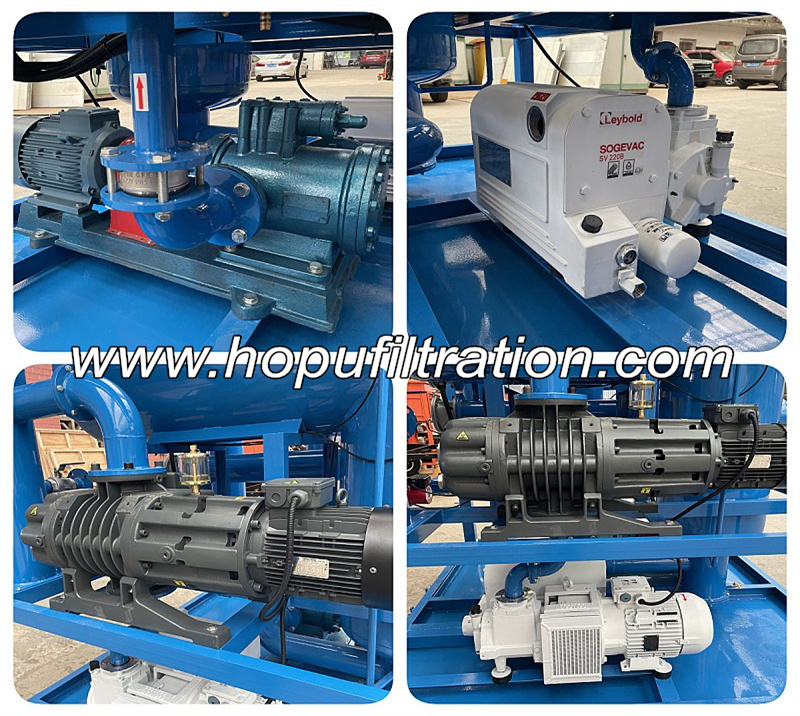

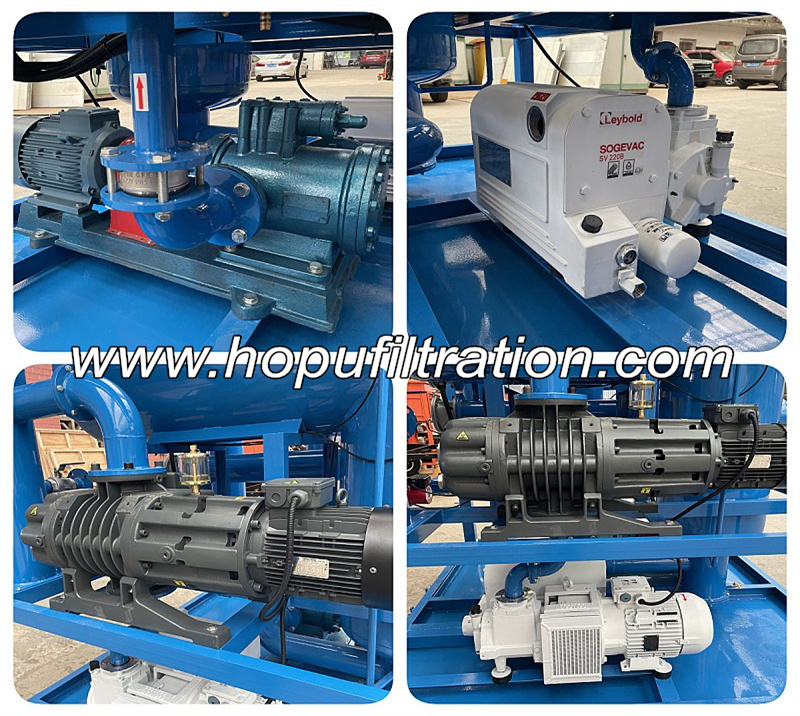

1.Double horizontal T-shape vacuum separators, combined with Duplex-Stereo film evaporation technology developed by HOPU chemical engineer.

Advanced double-stage large capacity dehydration and degassing system which adopts large area three-dimensional flash evaporation technique ,

2.Widely used for transformers on-site installation or maintenance to fill oil into transformers and circuit breakers under vacuum condition or conduct transformers evacuation operation.

3.Precise filtration system, high-quality filtering elements and multi-stage filtration with gradual precision.

4.Equipped with automatic temperature control system, liquid-level control system, defoaming control system, pressure protection system and high quality main components.

5.The machine supports on-line operation without supervision with indicators to show operation status.

6.The machine adopts humanization design with low noise, easy operation, long free-maintenance time and energy saving to lower the operation cost.

7.With electrical control inter-lock design. Vacuum system, oil pump system and heating system are interlocked in control.

8.Equipped with indication for changing filters and automatic stop device for overloaded filters.

9.Equipped with emergency stop for electric leakage and power overload to protect the motor.

10.With phase-sequence, phase lose protection function and safety control for sudden shut-down.

11.Equipped with vacuuming interface for transformer evacuation operation.

12.The outlet and inlet can be interchanged.

Technical data (HOPU 2024 version)

| Item | Index | Unit | ZYD-30 | ZYD-50 | ZYD-100 | ZYD-150 | ZYD-200 | ZYD-300 | ZYD-500 |

| Technical Parameter for Purifier | Flow Rate | L/H | 1800 | 3000 | 6000 | 9000 | 12000 | 18000 | 30000 |

| Working Vacuum Degree | MPa | -0.08~-0.0999 |

| Limited Vacuum Degree | Pa | ≤7 |

| Working Pressure | MPa | ≤0.5 |

| Constant Temperature Control Range | ℃ | 20-70 |

| Power Supply | V | 380V/50Hz(Can be customized) |

| Working Noise | dB(A) | ≤70 |

| Total Power | KW | 30+3.3 | 40+3.7 | 60+7.4 | 90+13.5 | 120+14 | 135+20.5 | 180+20.5 |

| Inlet/Outlet Diameter | mm | 25 | 32 | 40 | 50 | 50 | 65 | 80 |

| Net Weight | Kg | 650 | 800 | 1000 | 1300 | 1800 | 2100 | 3500 |

| Overall Dimension (L×W×H) | cm | 120×132×180 | 120×136×185 | 154×185×216 | 223×172×240 | 223×172×24 | 345×200×250 | 365×210×250 |

| Oil Index After Treatment | Breakdown Voltage | KV | ≥80 (GB/T507), Sphere Gap Test |

| Water Content | ppm | ≤5(GB/T7600) |

| Gas Content | % | ≤0.3(GB/T423) |

| Filtration Precision | μm | ≤1 |

| Ethyne | % | 0 |

Optional design for HOPU Vacuum Dehydration Insulation Oil Purifier System

1.PLC intelligent control with touch screen operation and operation status dynamic display.

2.Online moisture tester, online particle counter and online flow meter with adding-up function.

3.Frequency converter for free adjustment of flow rate

4.The whole structure of the machine: mobiles style with four wheels, fixed style, mobile style with trailer(double axles or single axle), fully enclosed style, conceal eaves type and open style of canvas etc.

We are profession exporter, provide service worlwide!

Your inquiry will be replied within 12 hours due to time zone difference

Your inquiry is warmly welcomed!

HOPU Website: www.hopufiltration.com

Branch 1: www.hpoilsolution.com

Branch 2: www.hopuoilpurify.com